1:

Is the 620A is in the

“RMT_STP” mode?

On the bottom line of the display it must read “LCL” for front

panel button control.

Go to the Programmer Configuration selection and change the mode

from “EXT COMPUTER” (RMT) to “FRONT PANEL,” (LCL) or make the

change from the computer if the selection is available.

2:

Is the “PROGRAMMER

SYNC” enabled?

From the “CONFIG

PROGRAMMER” selection, page down six times.

If the display indicated the Sync is

Enabled.

Push the SEL button to select

Disabled.

Push Reset and try Run again.

3:

Is there a flashing “S1 or S2” in the

ALM: field on the front panel?

If the S1 or S2 is flashing the offending channel will also be

displaying either P.OP or RANGE in the PV field on the front

panel display.

P.OP

- indicates a probe open condition.

Either the thermocouple or RTD input

is open or the current or voltage input is out of the usable

range.

Correct the open probe condition and the control channel will

immediately read the current PV value.

If the P.OP condition can not be corrected the Analog input

board of the instrument may be damaged.

Contact TMC Services for repair services.

RANGE

- indicates that programmed or manual setpoint entered is

outside of the Span-Setpoint Limits range configured for the

control channel.

If the setpoint appears to be within the desired usable range

check the controllers Span-Setpoint limits.

They may have been changed and not

restored.

The limits determine the Max and Min

setpoints that can be entered.

They also determine the total span

of the controller.

A Max of 200 and Min of -100

establish a span of 300.

Manual Mode:

From the Manual Mode screen enter a new setpoint within

acceptable limits.

The controller will immediately

resume operation.

Programmer Mode:

1 - Check the programmed setpoint.

It must be within the usable span of

the controller

2 – When starting a program, or changing and starting on a new

step, a corrupt setpoint can be

generated.

When this occurs the setpoint must

be corrected to “wake up” the controller.

Select

the manual mode and enter a setpoint as mentioned above.

Be sure to place the control channel back into programmer mode

and try running the program.

3 - If the span was incorrectly set and is adjusted to correct

values the control channel will correct itself

and resume operations.

4:

Is there a flashing “L1

or L2” in the ALM: field on the front panel?

The L1 (CH1) and L2 (CH2) are DEV (deviation) alarm indicators.

The DEV value can be entered by the operator in the

Manual Mode or in the Edit mode on each step of the program.

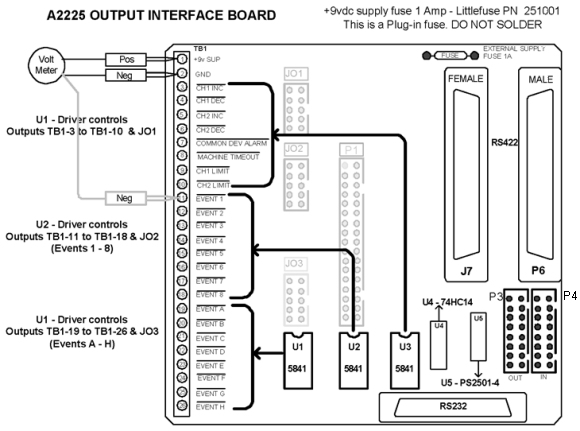

There is a “Common DEV Alarm” output on TB1 of the A2225 Output

Interface PCB. This

output goes Active whenever the L1 or L2 ALM: display is

flashing.

Each channels DEV alarm can be configured for 4 different modes in the

Programmer Configuration.

In any mode, the L1 or L2 will display on the front panel and the output

pin will be active if the DEV condition exists.

The available modes for each channel are:

1 – During DEV the programmer Runs or Stops.

2 – Alarm Output Resets Automatically or Manually.

Run – Automatic Reset:

If a DEV condition exists.

The programmer will continue to run the program.

The L1 or L2 will flash in the ALM field and the output

will be active.

When the DEV error is corrected the output de-activates and the L1 or L2

display goes blank.

Run – Manual Reset: If a

DEV condition exists.

The programmer will continue to run the program.

The L1 or L2 will flash in the ALM field and the output

will be active.

When the DEV error is corrected the 620A will continue to run with the

output active and L1 or L2 flashing in the ALM field.

If the DEV condition no longer exists the Run button

must be pushed to

acknowledge the DEV alarm was active.

The output will de-activate and the L1 or L2 display goes

blank.

Stop – Automatic Reset:

If a DEV condition exists.

The programmer will stop (freeze/hold).

The clock stops and the setpoints are latched at the

current values. The

L1 or L2 will flash in the ALM field and the output will be

active.

When the DEV error is corrected the output de-activates, the L1 or L2

display goes blank, and the programmer automatically resumes

operation from the point it was stopped.

Stop – Manual Reset: If

a DEV condition exists.

The programmer will stop (freeze/hold).

The clock stops and the setpoints are latched at the

current values. The

L1 or L2 will flash in the ALM field and the output will be

active.

If the DEV condition no longer exists the Run button

must be pushed to

acknowledge the DEV alarm was active.

When the DEV error is corrected, and the run button is

pushed the output de-activates, the L1 or L2 display goes blank,

and the programmer resumes operation from the point it was

stopped.

Note: The error must be within the DEV limits for the program to resume

when the run button is pushed.

Otherwise the program will remain stopped.

Back to the top.

My Program runs but the setpoint does not

change.

Look at the setpoint field on the front

panel.

If the decimal point is the letter

“m” then that channel is in

the manual setpoint mode.

Manual setpoints override programmed

setpoints in a program.

Select “Manual” from the main menu and

change the channel from Manual to Programmer.

The “m” will go away and the decimal

point will return indicating the controller channel is now in

programmer mode.

Back to the top.

My control

channel reads P.OP or a very low or high value.

How do I check it?

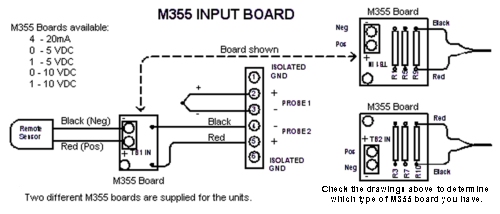

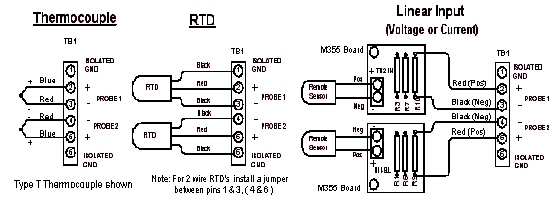

A simple check can be made to verify that the analog board input is

functional. This check can not be used for RTD inputs.

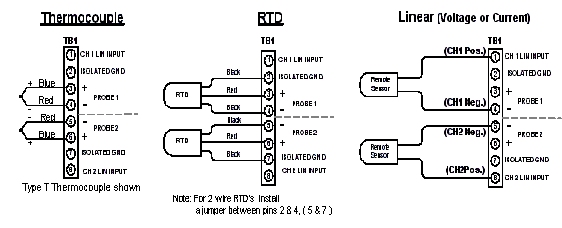

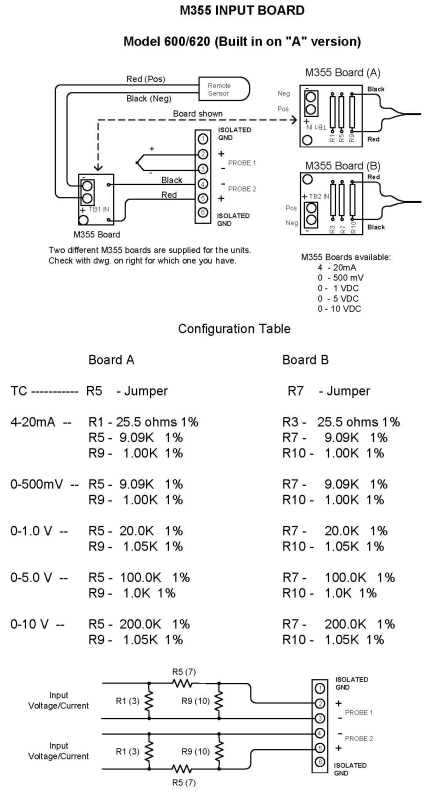

Thermocouple or Linear input types:

Go to the Controller configuration and select Degrees C for the Units

and Type_T_TC for the Input.

Remove the sensor wires from the input terminal block.

Using a jumper (a piece of wire or paper clip works nicely) short the

thermocouple input pins probe 1 (or 2) plus and minus.

The control channel should read the temperature of the Cold Junction

Device, approximately 25 to 40 deg C and be stable. If not,

contact TMC Services for repair options.

If it is good a calibration may be necessary.

Configure the channel for its correct units and input

type and perform a calibration.

RTD:

Disconnect the three wires from the RTD to the input terminal strip.

Connect a 100 ohm resistor across the Probe 1 plus and minus input pins.

Connect a jumper across the ISO GND and negative input pins.

The controller should read 0.0.

If the reading is off a calibration may be necessary.

If the controller still reads P.OP contact TMC services for repair

options.

Back to the top.

I can't

get anything to work or make changes from the keypad of the

controller.

Is the unit in

“RMT_STP” mode?

Push the “RESET” button on the controller.

If the Bottom line says “RMT” it’s in the remote mode and

will only take commands from a computer.

If the display reads “RMT_STP.”

Push RESET, PAGE DOWN,

4, 1.

Use the arrow keys to position the cursor over the

“EXT_COMPUTER” display.

Push the “SEL” key until the display reads “FRONT

PANEL...”

Push the “RESET” button.

The bottom line should read “LCL_STP.”

You now have front panel control.

Is the unit in “RMT_RUN”

mode?

If so, follow the

procedure below.

If the unit is interfaced with a computer

issue a command to return it to the “LCL” Local front panel

mode.

If the unit is not connected to a computer or

if the communications have been disrupted and can not be

reestablished proceed as follows.

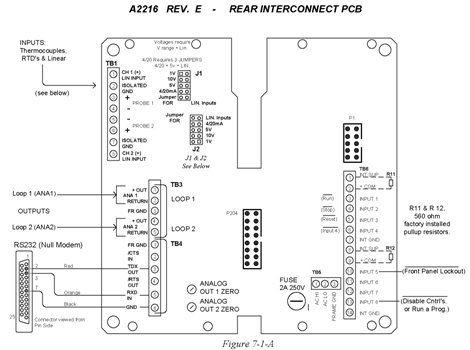

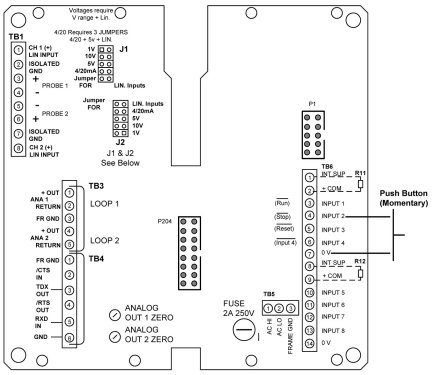

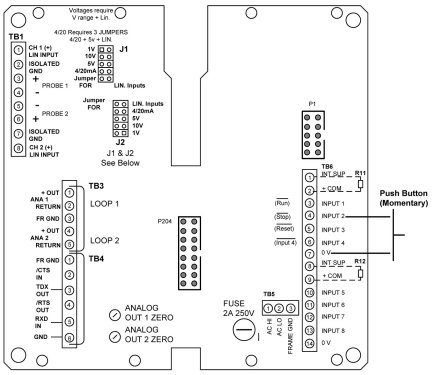

Refer to the diagram below for the A2216, TB6 and

pin outs.

This drawing is

also in the 600(A) / 620 (A) Manual Chapter 7 page 2A (Available

Here).

Connect a momentary switch across TB6 pins

4 (Input2, Stop) and 7 (O v).

You may want to leave the switch connected for future

use.

Pushing the switch will put the unit into

the “RMT_STP” mode.

Use the procedure above to regain access to

the LCL (Front Panel) mode of operation.

Back to the top.

I can't

get the RS-232 communications to work with the ToolBOX software.

The ToolBOX software is designed to also

access addressable units with the RS 422 interface.

The ToolBOX software, even in the RS232 mode,

is address sensitive.

The default address is 1.

The 620A address selection is made on the

first page of the “Programmer Configuration” selection.

Using the “SEL” button change to 422.

Either change the 422 address to 1 or note the address

and use it for the address selection on the ToolBox Software.

Don’t forget to change the selection back to

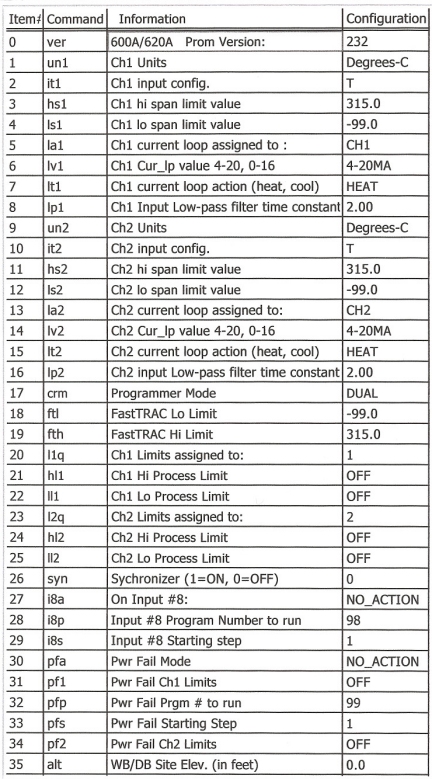

232 before exiting.

Make sure the Baud Rate and Parity match on

both the ToolBox software and the 620A instrument.

Set the

computer Comm port in use to flow control of “xon/xoff.”

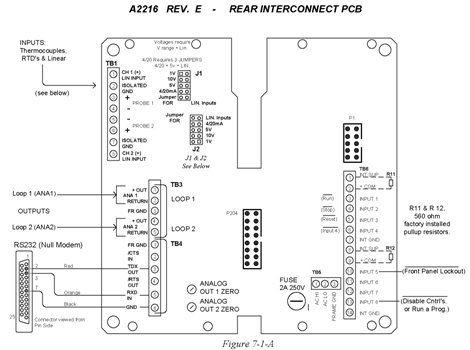

The 620A ships with the RS232 connector wired

for “null modem” operation. See below and also in the

600(A) / 620 (A) Manual Chapter 7 page 2A (Available

Here).

If the RS 232 cable is not null modem swap the

orange and red wires on TB4.

Back to the top.

What is

the difference between an EOP and a LOOP step?

The two steps are similar.

A LOOP step can

repeat a user defined section of the program. When the loop

counter reaches zero the programmer advances to the next step in

the program. Each

loop can perform from 1 to 9999 loops.

Loops can be nested, or two loop steps can be programmed

back to back with 9999 loops to repeat the same section of code

9999 x 9999 or 99,980,001 loops.

Every program

“MUST” be terminated

with an EOP step.

An EOP step can repeat a user defined section of the program, including

loops or nested loops, and will stop when the Cycle counter

reaches zero.

Similar to a Loop step the user

defines the step number of the program to cycle back to and the

number of program cycles to execute, up to 9999.

When the EOP cycle counter reaches zero the

program stops and latches the last CH1 & CH2 setpoint values and

event ON/OFF status.

CAUTION:

Care must be taken when changing the step

number for the EOP or entering a new program with less steps

than the existing program in memory.

Reference the information below for details.

AVOID TURNING AN EOP STEP INTO A LOOP STEP

If a program is entered into a

program location that has an existing program, and the new

program is shorter than the original one, the first EOP step

will be treated as a LOOP step.

When entering a new program into

a location that currently has a program in it, the following

procedure must be taken.

ERASE THE EXISTING PROGRAM - This

is the recommended procedure.

From

the Edit screen move the cursor so it is flashing on the program

(notstep) number, then push the DELSTEP button.

This will erase the existing program and the display will

read "PROGRAM EMPTY, PUSH PAGE DOWN".

Pushing the PAGE DOWN button will insert the first step in the

program location.

Enter the new program terminating it with an EOP step.

ENTER NEW PROGRAM INFORMATION- This can only be done if the new

program has more steps than the existing program.

If it does not then the EOP step from the original

program will still be present somewhere after the new EOP.

The first EOP step will be treated as a LOOP by the

programmer when the program is run.

The second EOP step will be treated as the true EOP.

In this situation the program will cycle (loop) as many

times as indicated by the first EOP, however it will be treated

as a LOOP Step and continue running the programmed information

following the first EOP to include cycling the entire program if

the second EOP step is programmed for more than 1 cycle.

CHECKING THE PROGRAM FOR

ADDITIONAL STEPS FOLLOWING THE EOP.

In the EDIT Mode pushing the page

down button will advance through the program in sequential step

order. However if

the first EOP step is reached and the PAGE DOWN is pressed the

unit will return to step 1 of the program.

The first EOP is recognized as the end of the program.

This WILL NOT indicate if any additional steps are

following the EOP.

Determine the step for the first

EOP in the program (i.e. step 10).

From the EDIT screen position move the cursor to the step

number and push the clear button.

The unit will go to step 1.

With the cursor on the step number, enter the number of

the step following the first EOP step (step11).

If this EOP step is the last step

in the program, the display will flash between the messages

"Invalid Entry" and the Ramp\Soak Program screen.

Push the RESET Button twice to

return the unit to the STOP screen.

This EOP is the last step.

If the programmer indicates

additional programmed steps following this EOP, this information

must be deleted.

Push the DEL STEP button for each additional programmed step.

Be careful not to delete the EOP

step itself. Each

time the DEL STEP button is pushed it deletes the current step

and pulls the following ones forward.

When the correct EOP step is displayed all information

that followed it is now deleted.

Check the program for additional

steps after the EOP (Just to make sure).

Back to the top.

I’m

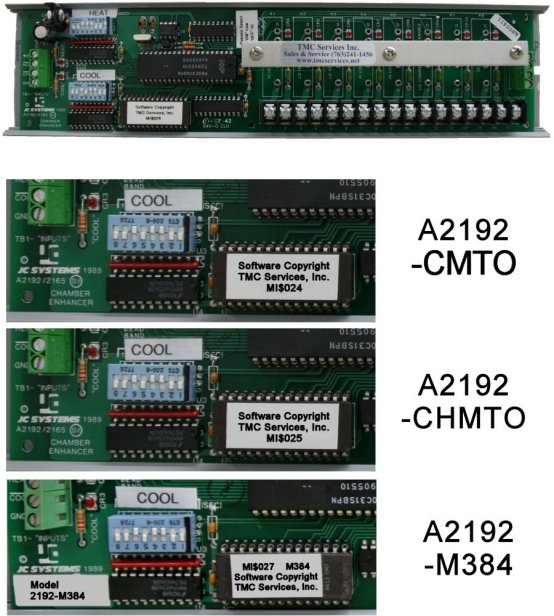

using an A2192 Chamber Enhancer Board. Are there any

mandatory settings?

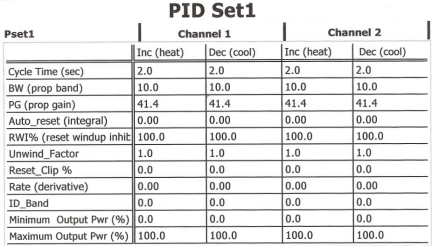

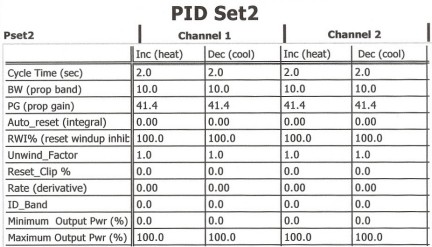

It is imperative that the Inc & Dec Cycle time

of the 620A control channel and the A2192 board Cycle time dip

switch settings match.

If they do not then the information interpreted by the

A2192 will be incorrect and result in incorrect output

functions.

See the A2192 manual for Heat & Cool Dip

switch definitions and settings.

Note:

The Model 620A is connected to the A2192 board by 4

wires. The wires

from the 620A are not pin for pin compatible with the input pins

of the A192.

620A ,TB1 Pin

to A2191, TB1

Pin

1

1

+9vdc

2

4

Gnd

3

2

Inc

4

3

Dec

Back to the top.

I have an Error message.

What does it mean

and what action should I take?

P.OP

on CH1 or CH2 PV:

A P.OP (open probe) condition is displayed

on the control channel PV display.

This message indicates an open input sensor or problem

with the input section of the analog PCB.

Click here

for control channel "P.OP" error

troubleshooting.

“Hardware Failure” or “Error” message:

The Model 620A/600A has several Error

Messages that display to indicate internal problems in the

instrument. The

messages may be displayed as

“Hardware Failures”

or

“Errors”.

These messages do not necessarily indicate

the item or area responsible for the error, but the area

impacted by the problem.

In most cases they provide advanced warning that a

problem has developed needing immediate corrective action or

will need corrective action in the near future.

Some of the messages indicate that a problem exists that

can be corrected and may not repeat itself.

Available Actions to resolve a problem:

In most cases two user actions are

available.

ENT

ignore:

If the

Enter button is

pushed the unit returns to its previous operating state.

Try pushing the Enter button.

After the instrument resets, turn the power

off for a minute or two then turn the power back on.

If the problem was related to scrambled or

incorrect information from an external source it may be

corrected and not reappear.

If the problem that created the error still exists the

message may return.

If the message returns, this may be the same

day or even several weeks, the unit will need an upgrade or

repair.

Contact TMC Services for repair options.

If the procedure above does not correct the

error a CLEAR erase should be

tried next (procedure is below).

Make sure all

programmer and controller configurations, PID settings and

programs you

need to keep are

recorded by hand or saved using the JC Systems

ToolBox software prior to

using the CLEAR

erase function.

CLEAR erase:

When the

Clear button is pushed the unit performs a “Cold Start”.

(Note that all of your unique configuration settings

will be lost when doing a cold start. Reference the

information above and another FAQ.)

All locations in memory and the EEPROM are

erased and factory default parameters are

installed.

A cold start will perform the following

action. All programs

in memory are erased and the program memory will have 200 blank

program steps. The

programmer and controller configurations will be set to

factory

default conditions: CH1 & CH2 for Type T

Input and factory default PID

tuning parameters installed.

The stored CH1 and CH2 controller calibration parameters

are erased.

After the cold start sequence is completed

all of the instruments parameters and programs mentioned above

must be reinstalled either via the front panel or using the

ToolBox software.

After the controller configurations are reset each controller

channel must be calibrated.

IMMEDIATE ACTION REQUIRED:

EEPROM error or CRAM error.

Two items that require immediate corrective

action are, EEPROM error, and CRAM error.

EEPROM error: The EEPROM

is defective or starting to go bad.

The ENT ignore procedure may correct this problem

temporarily but it is certain to return.

With each occurrence it will return more frequently.

Contact TMC Services for

repair options.

CRAM error: The most

common item that produces this error is the lithium battery.

It is

recommended to replace the battery every 5

years. Reference the

battery replacement instructions in another

FAQ.

Once the battery has been replaced, the

problem should go away.

If not, then the CRAM device must be replaced.

It may be a good idea to replace both components at the

same time.

Contact TMC Services for

repair options.

Back to the top.

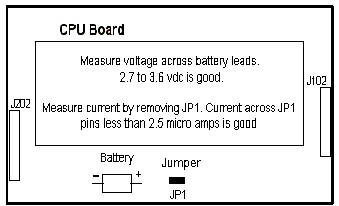

How do I replace the Battery in Models

600(A) and 620(A)?

**CAUTION**

DO NOT lay the CPU Board on a conductive surface. The

battery may short out!

Remove power from the unit.

Viewed from the rear of the unit. The right side of the

output Interface PC Board is mounted on hinged standoffs.

DO NOT remove the right side screws. Remove

the two screws on the left. Swing aside the board on the

rear of the unit to gain access to the Rear Interconnect PCB.

Remove the eight mounting screws securing the Rear Interconnect

PCB to the unit frame. Slide out the center (CPU) PC

Board.

The Model 620(A)/600(A) has a 10 year lithium battery.

Check the battery first before replacing it.

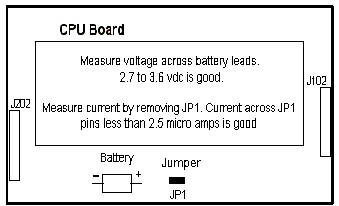

Voltage Check:

Measure the battery using a DVM set on the DC volts setting.

If the meter reads between 2.7 and 3.6 VDC the battery is still

good and does not need replacing. If the meter reads below

2.7 VDC, replace the battery with a recommended replacement.

(Saft, Lithium 3.6V PN LS 14250 or equivalent.)

Current Check:

Locate jumper JP1 and remove it. Set the meter to read

current (micro amps). Hook the meter up across the JP1

pins. The current should be less than 2.5 micro Amps.

Replacement:

Locate jumper JP1 and remove it. This will disconnect the

battery circuit from the rest of the board and prevent damaging

other components when soldering in the new battery.

On the component side of the board remove (scrape off) the

silicon beads protecting the solder joints.

It is best to cut the leads and remove the old battery first.

Then carefully unsolder the leads making sure to not lift the

pads on the board. Make sure the feed-throughs are free of

solder and the axial leads of the new battery can be installed.

Properly orient the new battery and solder it in place. It is

recommended to place a silicon bead over the battery connections

on the clad side of the board.

Replace jumper JP1 and reassemble the unit.

Replacement is complete.

Back to the top.